What are Graphite Usage Areas?

Due to its softness, it is used in pencil making and lubrication of moving metal parts, and due to its resistance to fire and acids, it is used in casting and refractory industry, crucible and laboratory materials. Black coloured refractory paints are generally made of graphite. Due to its good electrical conductivity, it is also applied in the manufacture of electrodes, motor brushes, battery rods and electronic devices. Graphite is also used as an additive material in tyres, car linings, matches and engine oils.

In Turkey, the industries that consume graphite in raw form are the pencil and foundry industries. Paint producers and iron and steel factories use imported graphite and its products. Graphite used in the foundry industry requires 60 - 70 per cent fixed carbon. In the pencil industry, this rate is over 95%.

Where is graphite used?

1. As Lubricant in Machine Parts

It can be used as a lubricant in machine bearings with its ability to adhere on machine parts for a long time. The graphite that can be used in this area must be very pure (at least 95% graphitised carbon) and must not contain hard minerals such as quartz. Depending on the type of carrier fluid, graphite forms a dry or wet layer here. The dry type is used in furnace chains and carriages, engine cylinders, marine vessels and chemical plants; the wet layer type is used in ball bearings under high pressure.

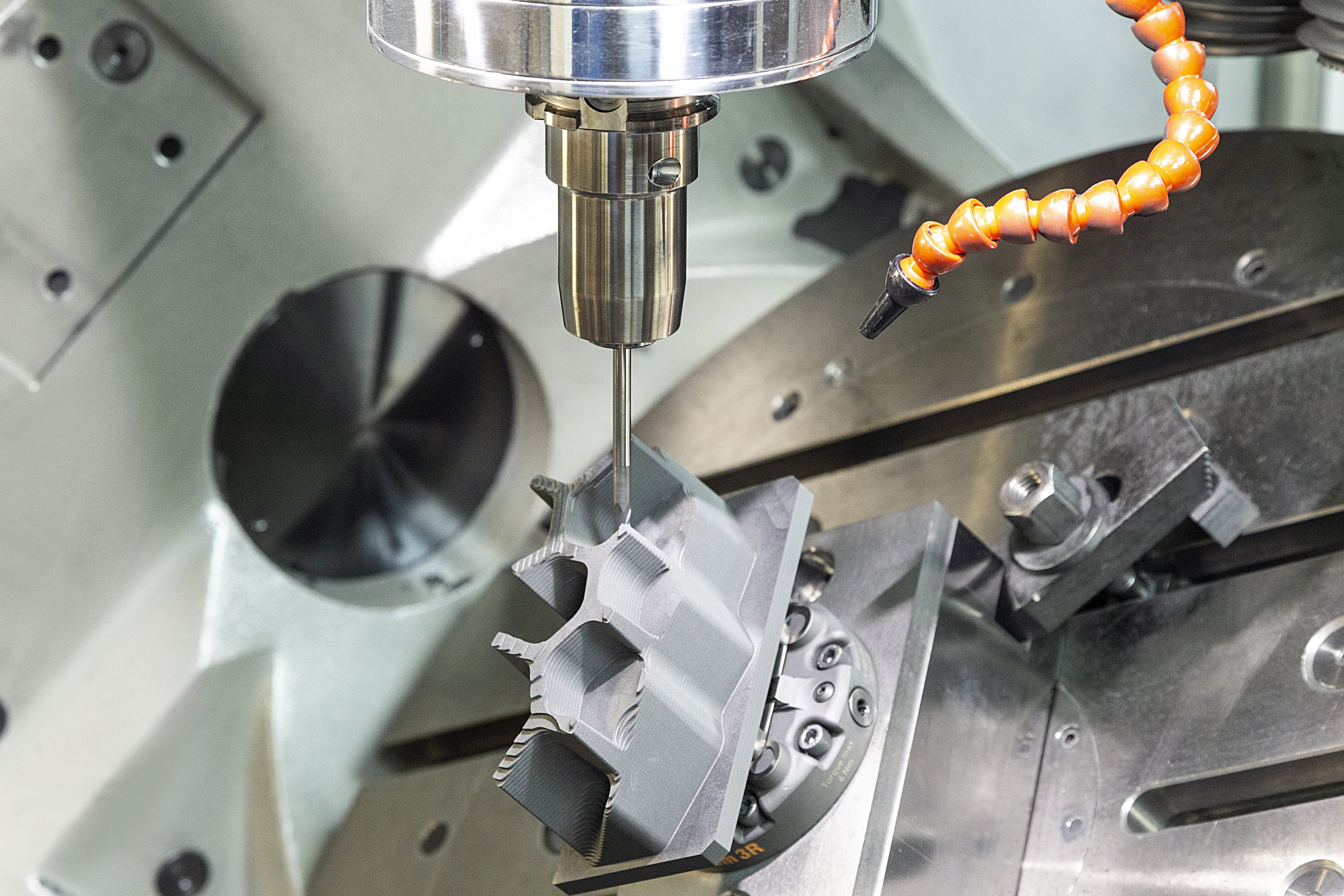

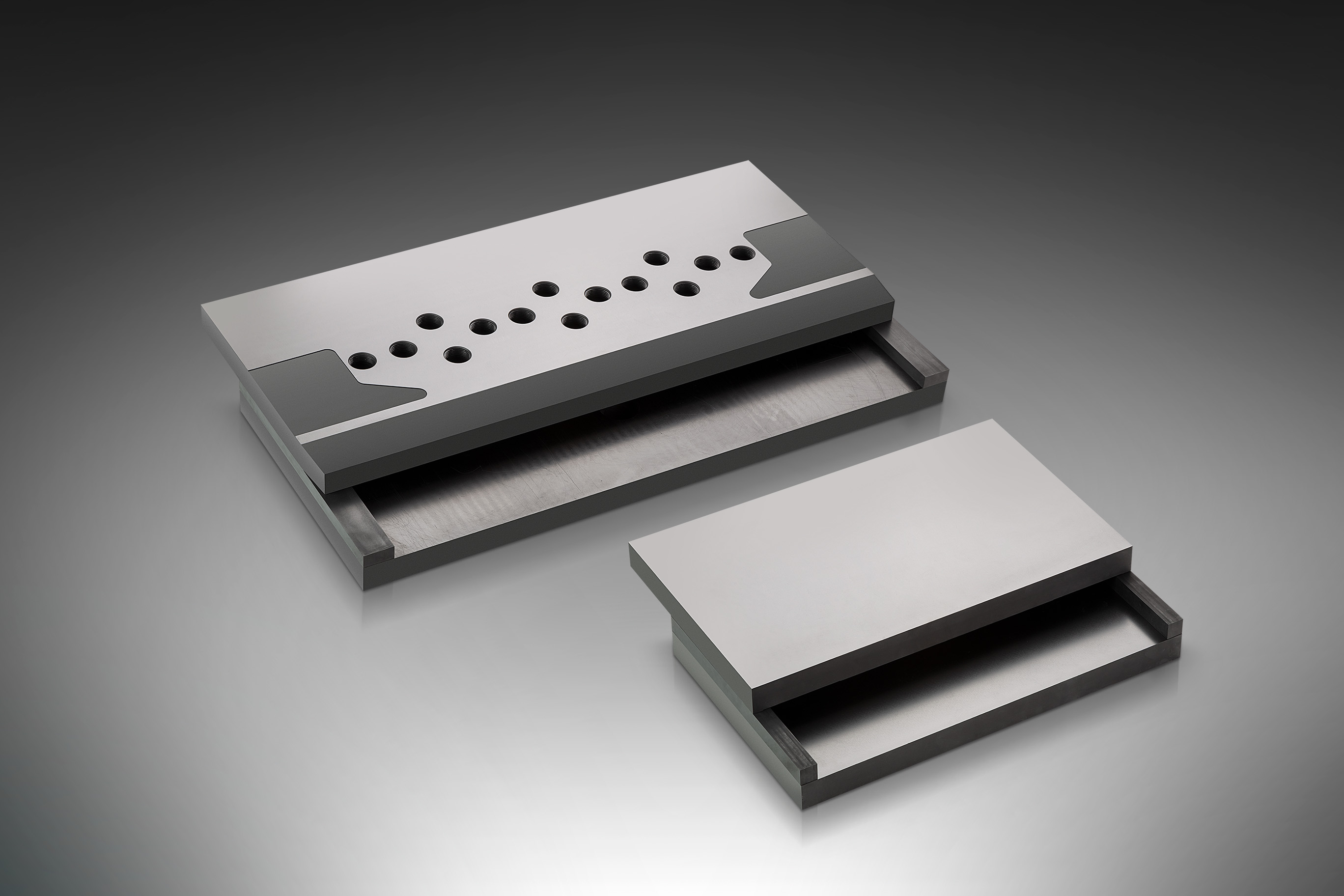

2. In Foundry Industry

Graphite powders containing 40 - 60 % graphitised carbon are mainly used in foundries. It is used in making casting moulds by mixing with clay and sand. Mixed with bentonite or olivine, ground coke powder and petroleum coke can substitute graphite in this industry.

3. In the production of pencil lead

The answer to the question "Is graphite used in pencil making?" is yes. Because the pencil lead is made from a mixture of processed kaolin, bentonite and graphite. The most suitable graphite type for this use is the fine-grained and compact one. Due to its softness, natural graphite is mostly preferred. Its value in this field increases in proportion to its high purity. Amorphous graphite is used for low quality pencil tips. In both cases, the desired graphite type is the one that does not contain abrasive material (such as quartz) and has 96% graphitised carbon.

4. In the manufacture of engine and generator brushes

These materials are made from high-temperature amorphous or vein-type natural graphite. Graphite suitable for this purpose must have a graphitised carbon content of more than 85%. Graphite and metal powders (copper or silver) bonded with pitch, tar or resin are used to make graphite brushes.

5. Other Uses of Graphite

In recent years, a large amount of graphite has been used in the dry battery industry. For this purpose, flake type (flaky) and graphite powder are the most suitable and must contain at least 85% graphitic carbon.

.jpg)

.jpg)

.jpg)