What is Continuous Casting? What are Continuous Casting Methods and Advantages?

What is Continuous Casting?

The process of solidifying the melted metal in the chamber in a certain cross-section with the help of a mould by cooling the area where solidification begins is called continuous casting process.

What are Continuous Casting Methods?

The mould content is determined according to the metallurgical properties of the material to be cast. Graphite is preferred as a mould for materials such as aluminium, copper, nickel, brass, gold, silver, bronze, etc. Since graphite has more than one area of use, manufacturers produce graphite with different properties with recipes specially prepared for the relevant applications.

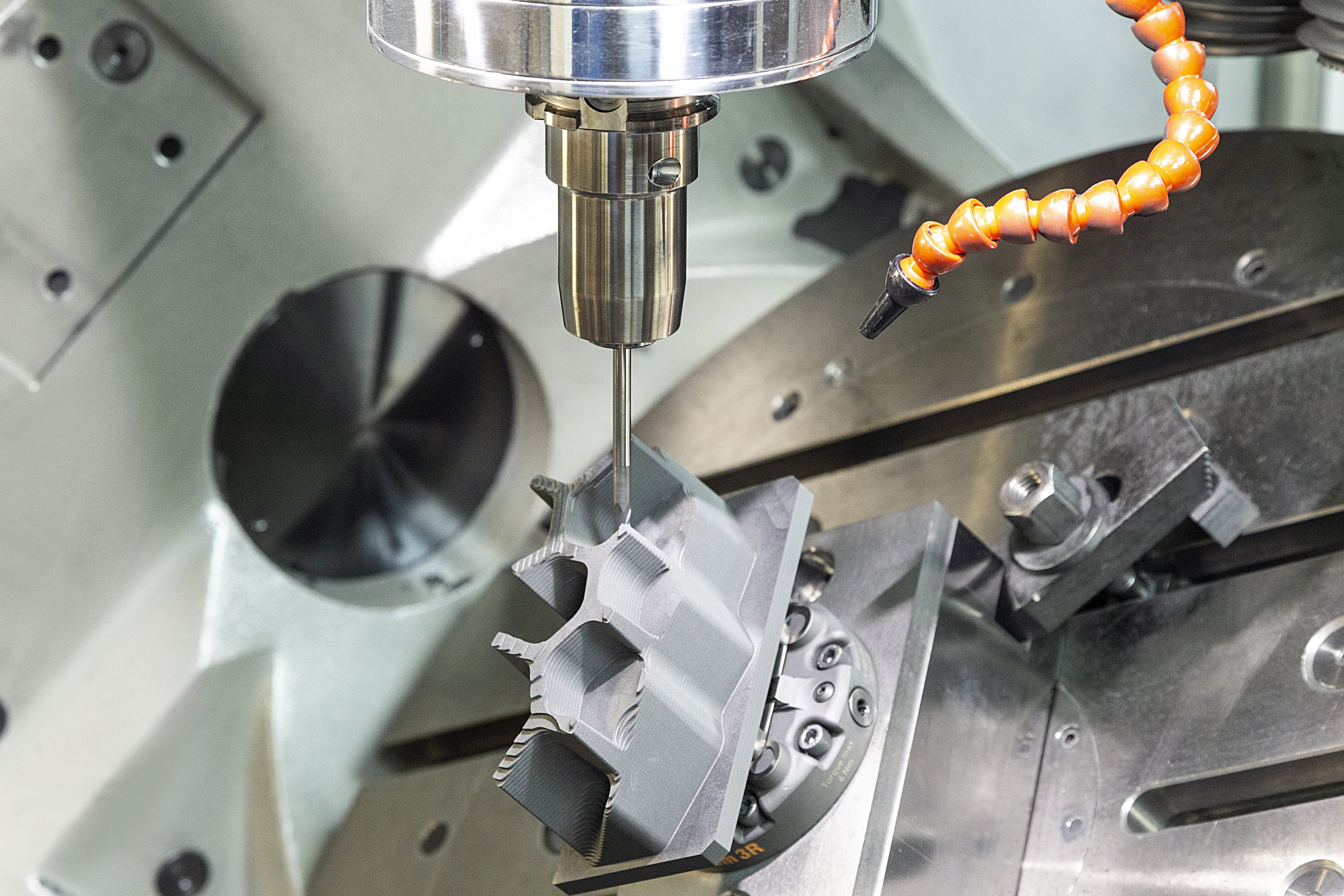

It is inevitable to encounter undesirable results if graphite is not selected suitable for the metal to be cast in continuous casting application. The most suitable graphite for the metallurgical properties of the metal in the continuous casting mould is determined by looking at the thermal expansion coefficient, thermal conductivity, grain size, porosity, etc. properties. After determining the correct graphite, the machining process, which is just as important, is started. Both the graphite selection and the machining process are of great importance in casting the molten metal in optimum quality from the moment solidification begins. Even if you have chosen your graphite correctly, an incorrectly machined mould may cause the melt to leak into unwanted areas and may adversely affect the solidification process of the metal.

.png)

.jpg)

.jpg)

.jpg)