Casting and Shaping of Precious Metals

Graphite is used in melting, casting and shaping of precious metals such as gold and silver, as well as in many areas due to its high temperature and thermal shock resistance properties.

Graphite gold melting crucible can be classified as F9 crucible, F6 crucible, F5 Crucible, F4 etc. as known in the jewellery industry. Gold melting crucibles are used with ceramic armour coating as well as without ceramic. This type of crucibles are generally used for the transfer of molten metal through the groove in the mouth. Graphite silver melting crucibles, like gold melting crucibles, are used for melting precious metals. Graphite crucible group is also classified as indutherm crucible, shot casting crucible (also known as granulating crucible or granulating crucible), Schultheiss crucible, Continuous crucible.

In addition to the graphite crucible group mentioned above, graphite stopper, graphite stirring rod, graphite cover, graphite lining throat or graphite throat, graphite core, graphite welding crucible, graphite washer, graphite screw washer etc. are other auxiliary graphite materials used in the casting and shaping of precious metals in the jewellery industry.

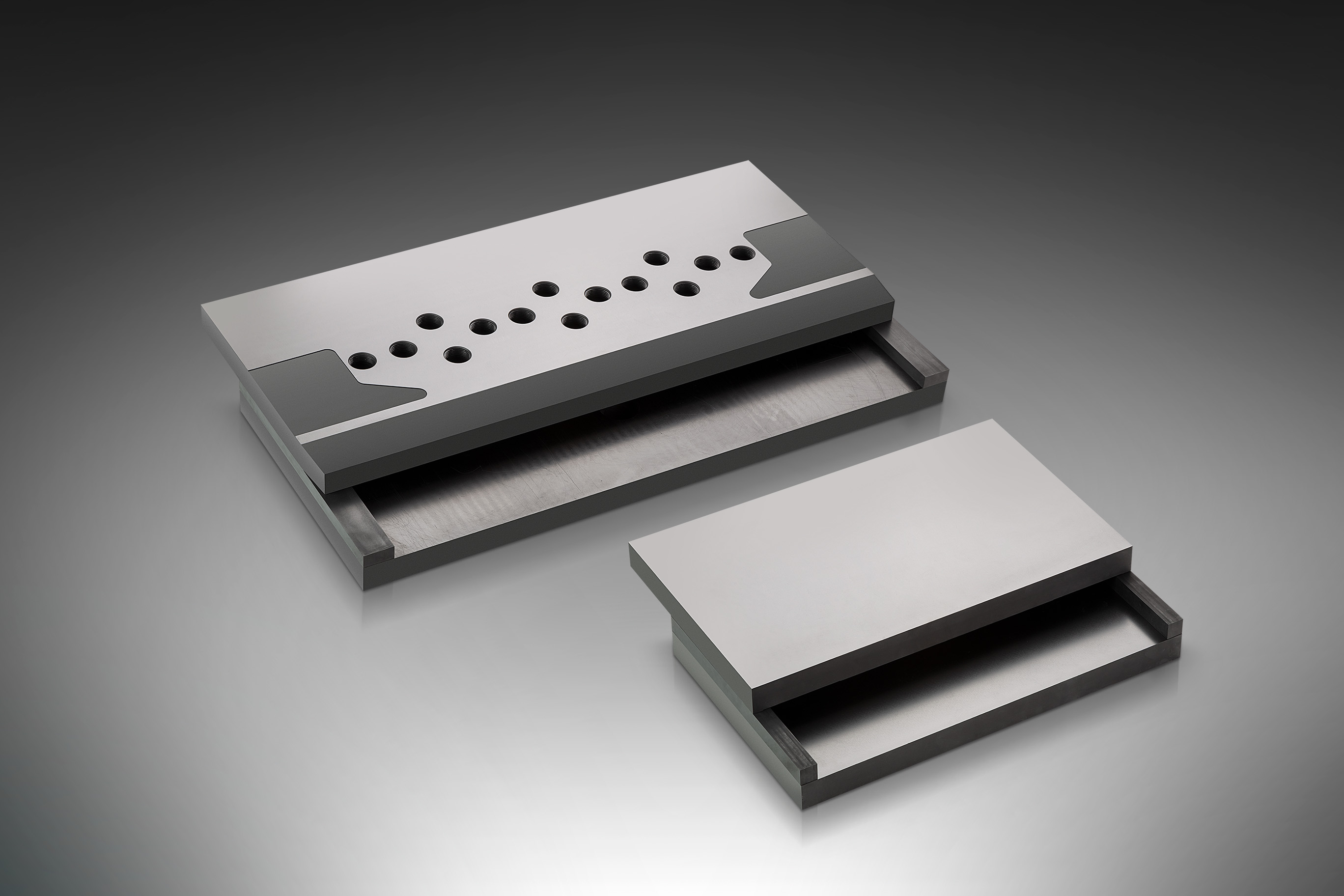

Graphite ingot mould (graphite gold ingot mould, graphite silver mould) and graphite wedge used as a distance adjuster between the ingot moulds are also widely used in gold refineries refining gold. Graphite ingot moulds are offered to our customers as two-cavity, one-cavity and four-cavity in desired sizes by machining method.

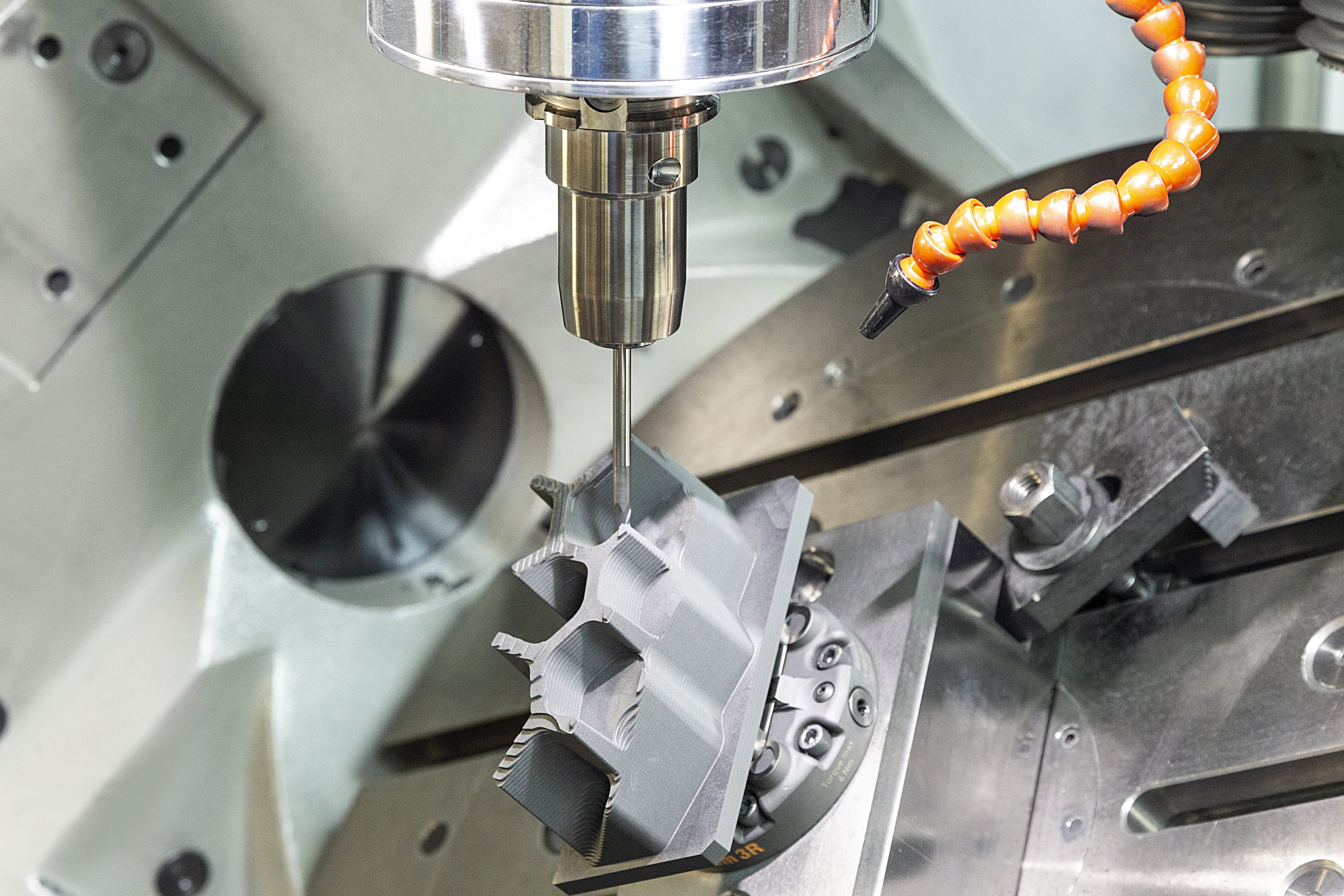

In addition, for accessories such as gold necklaces, gold tags, etc., we offer our customers graphite necklace tray or graphite tag tray manufacturing, which you can provide ease of assembly and welding with graphite mould design suitable for the form of the accessory, by processing with the desired precision on advanced technology CNC benches.

In order to obtain the desired result in liquid metal, liquid metal shaping process and final product, which is an important stage of precious metals, the use of graphite that is technically most suitable for the relevant process is the most crucial point of the work. Thermal shock resistance, grain size, density, thermal conductivity, porosity, etc. An incorrectly calculated graphite selection will lead to the deterioration of the homogeneous structure of such a valuable material and loss of time and labour.

As SKC KARBON, with our 60 years of experience in the graphite sector, with the understanding of correct analysis, correct service, we start our process with the selection of the most suitable graphite for your material, followed by 3D and 2D drawings prepared by the technical design team, and then we process them with the most precise surface quality with the most precise surface quality with the 5 axis machining centre C axis CNC lathe group on advanced technology CNC machines, which are among these machines, and perform measurements on the 5 axis CMM measuring device and provide service with our quality management system and total quality understanding that does not compromise on quality.

.jpg)

.jpg)

.jpg)