Graphite Electrode Replaces Copper in Plunge Erosion!

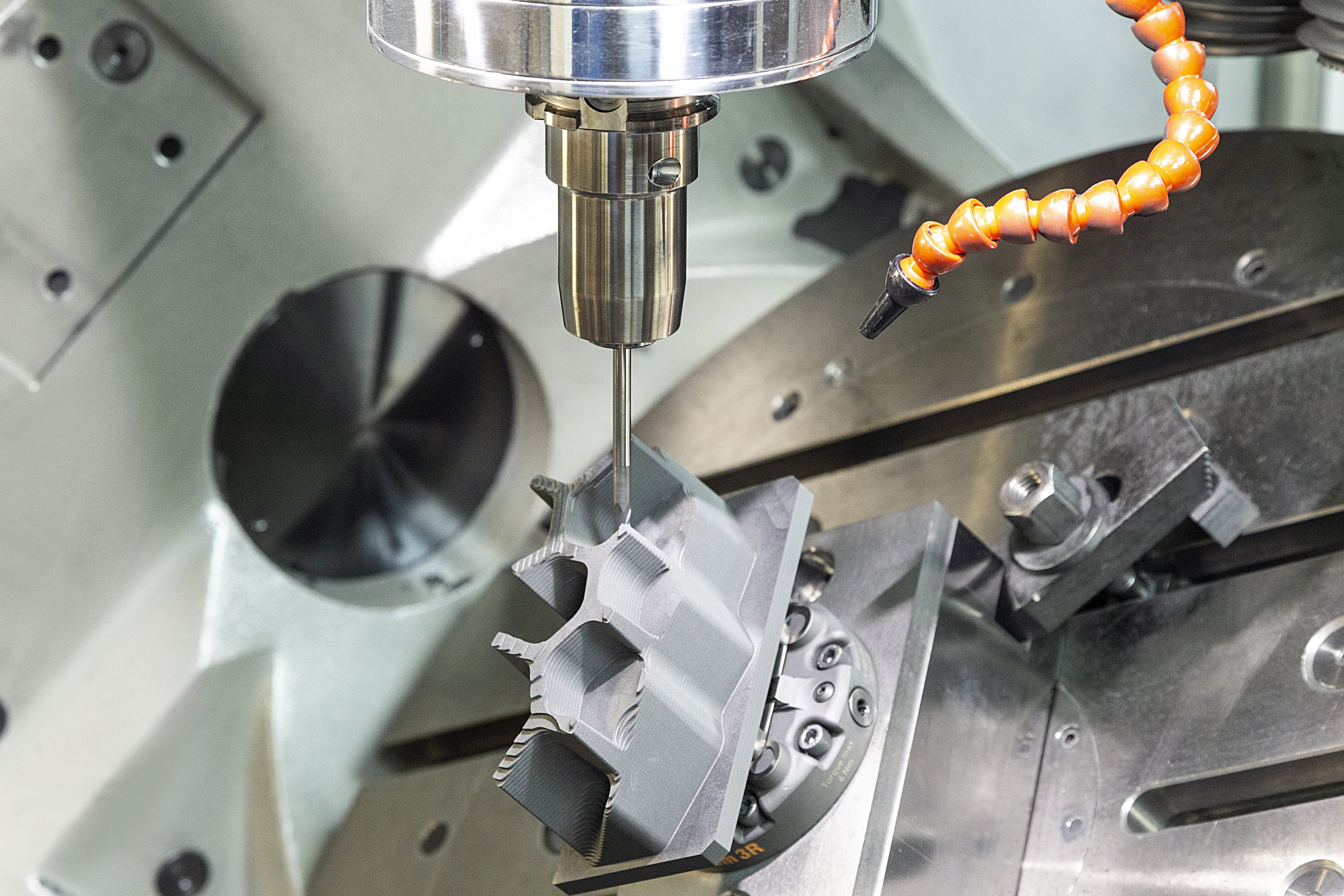

Especially preferred in the moulding sector, the process of shaping the workpiece by arc method by applying electric current to the conductive material is called the plunge erosion method.

The plunge erosion process, which was traditionally performed using copper, has been replaced by the use of graphite over time due to the many superior advantages of graphite over copper, as we will explain below.

The technical advantages and price performance indicators of graphite use have attracted users and ensured the widespread use of graphite.

With all these developments, a professional technical analysis and study should be carried out for each different plunge erosion process and the correct graphite quality should be determined.

Since graphite is a material with a wide range of uses, the selection of the right graphite in a special process such as plunge erosion, the correct processing methods and ideal surface quality are the most important parameters of the work.

SKC KARBON serves its customers with its industrial experience dating back to 1963, expert technical staff and unique machine park in the sector. It has become an assertive place in the EDM electrode sector in a closed area of 11.000 m2 with the latest technology CNC machines, especially the five-axis machining centre and the five-axis CMM device that can measure the processed part at the micron level.

So Why Use Graphite Instead of Copper?

1. Graphite is much lighter than copper. The difference between the densities is about 1/4 (Copper=8,96 gr/cm3 and Graphite=1,83 gr/cm3).

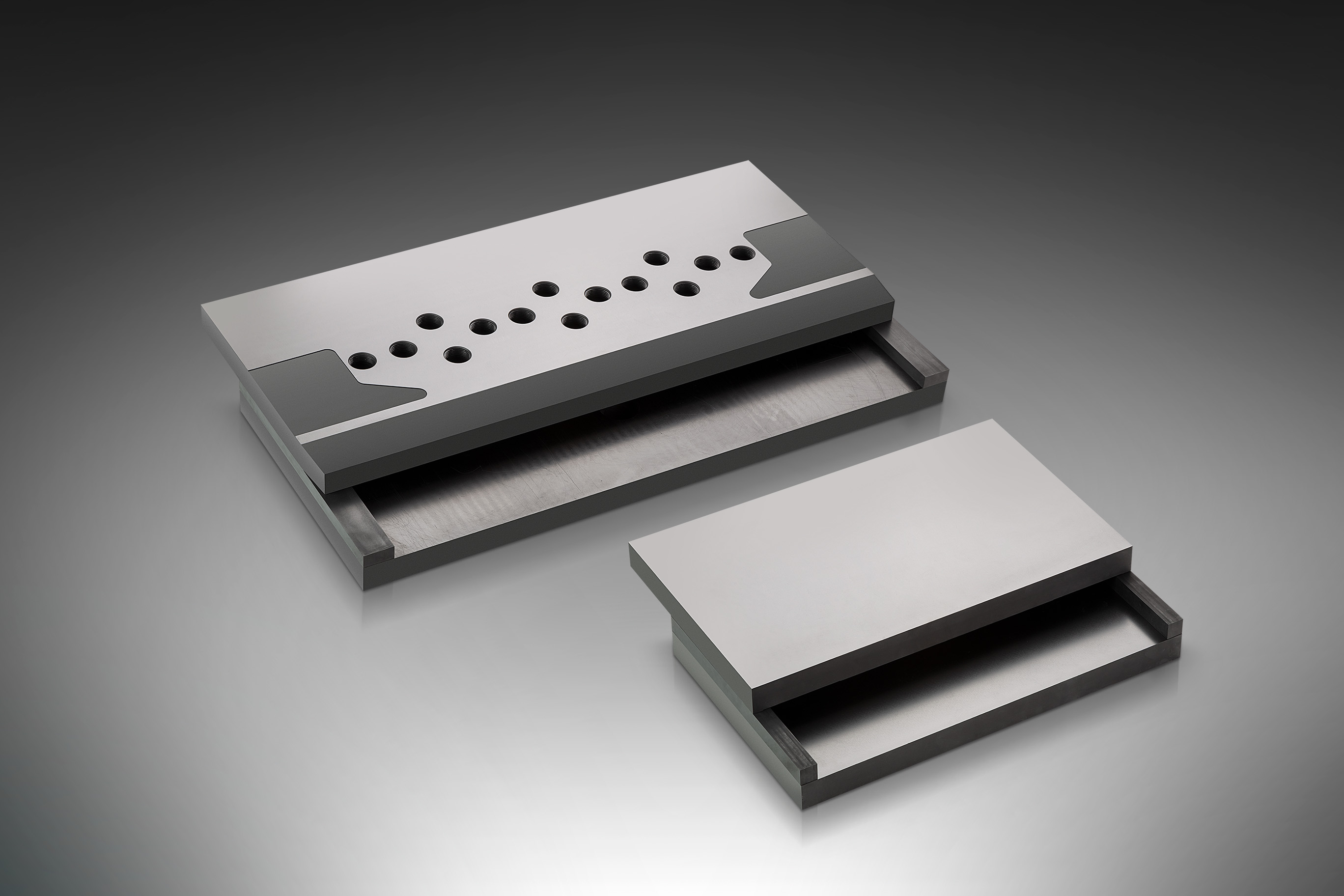

2. Graphite allows machining at much tighter tolerances and much thinner federates than copper without stretching. Copper federates in the range of 0.3 -0.5mm may cause stretching during machining and may cause mould defects during processing. Graphite can be machined without flexing due to its brittle structure.

3. Graphite can be processed much faster than copper. While copper causes burring and winding in chip removal, graphite, due to its structure, only removes dust from the area where the milling cutter is in contact and does not burr. (Up to 40% cutting speed increase - electrical resistance)

4. Graphite provides a much better surface quality than copper with its fine grain structure and processing speed.

5. The processing time is approximately 30% faster than copper and provides significant time savings in processing time.

6. The price fluctuation in unit prices is higher in copper than in graphite.

7. In case of skewing as a result of incorrect diving into the part in copper, it causes chip removal in an undesirable form and we may encounter an unwanted shape. Since the behaviour of the graphite part in this situation will be in the direction of fracture, it will not damage your part. This protects you from costly mould damage.

SKC KARBON, as a local company in the field of Carbon Graphite, aims to minimise the costs of our customers and optimise the quality with a professional approach and fast service.

.jpg)

.jpg)

.jpg)