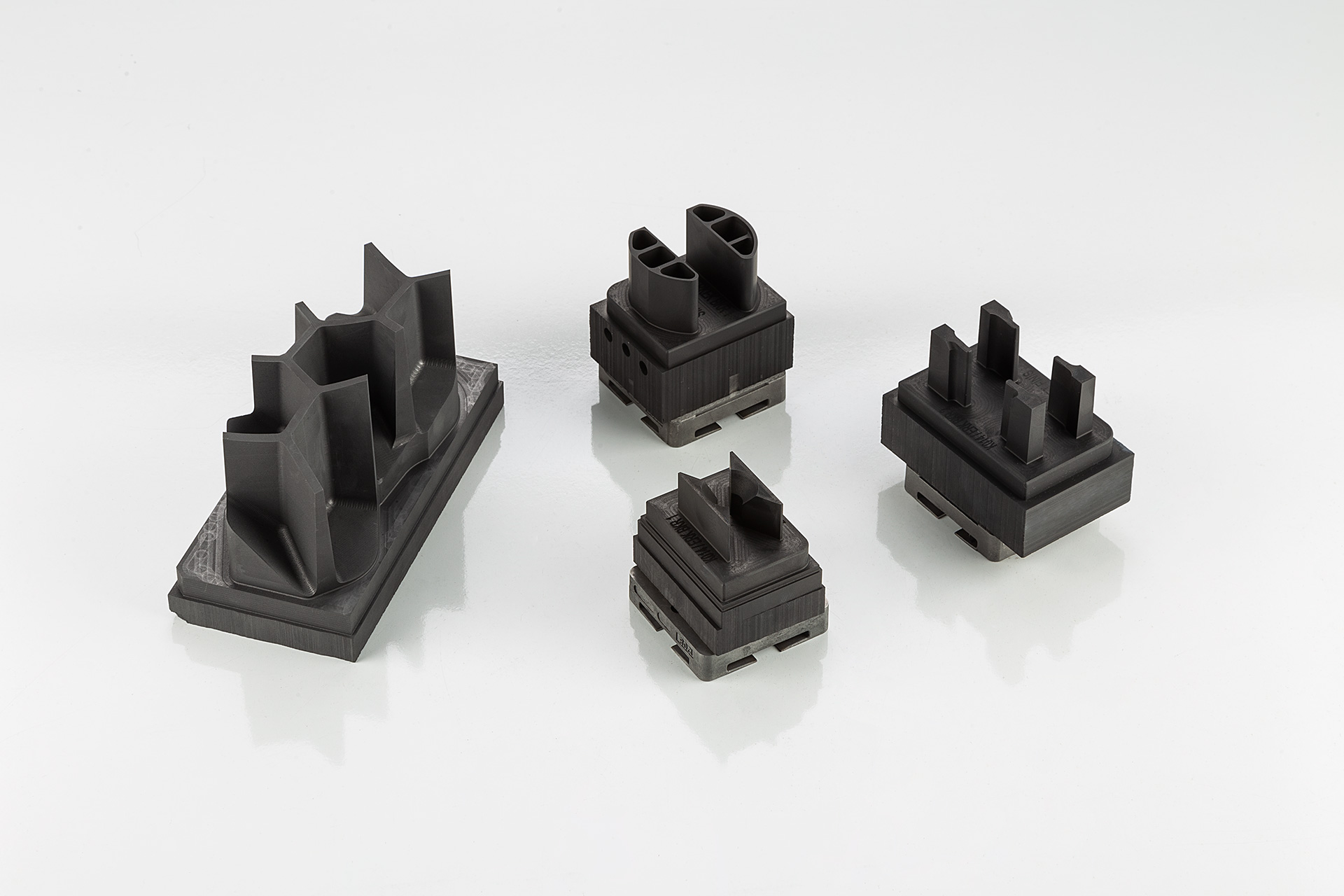

Finished or semi-finished (block) graphite electrode products for plunge (electro) erosion applications of various molds and workshops where machining is performed.

For your plunge erosion (EDM) applications, different graphite grades suitable for roughing processes; with superior surface properties, long life and high performance, to be delivered as semi-finished products or semi-finished products (blocks) processed to final dimensions: Insulating graphite

Graphite-Copper comparison for electrode use in plunge (electro) erosion applications:

1. Density difference (d Copper=8.96 gr/cm3 and d Graphite=1.77 gr/cm3): lightness

2. Graphite's ability to be machined to tighter tolerances than copper and its rigidity advantage

3. Faster machining with graphite (up to 40% increase in cutting speed - electrical resistance)

4. High oxidation resistance at room temperature with the storage and transportation advantage of graphite

5. Superior part surface properties can be achieved with graphite

6. Economy in graphite unit prices and low price fluctuations compared to copper

.jpg)